TREATMENT PROCESS

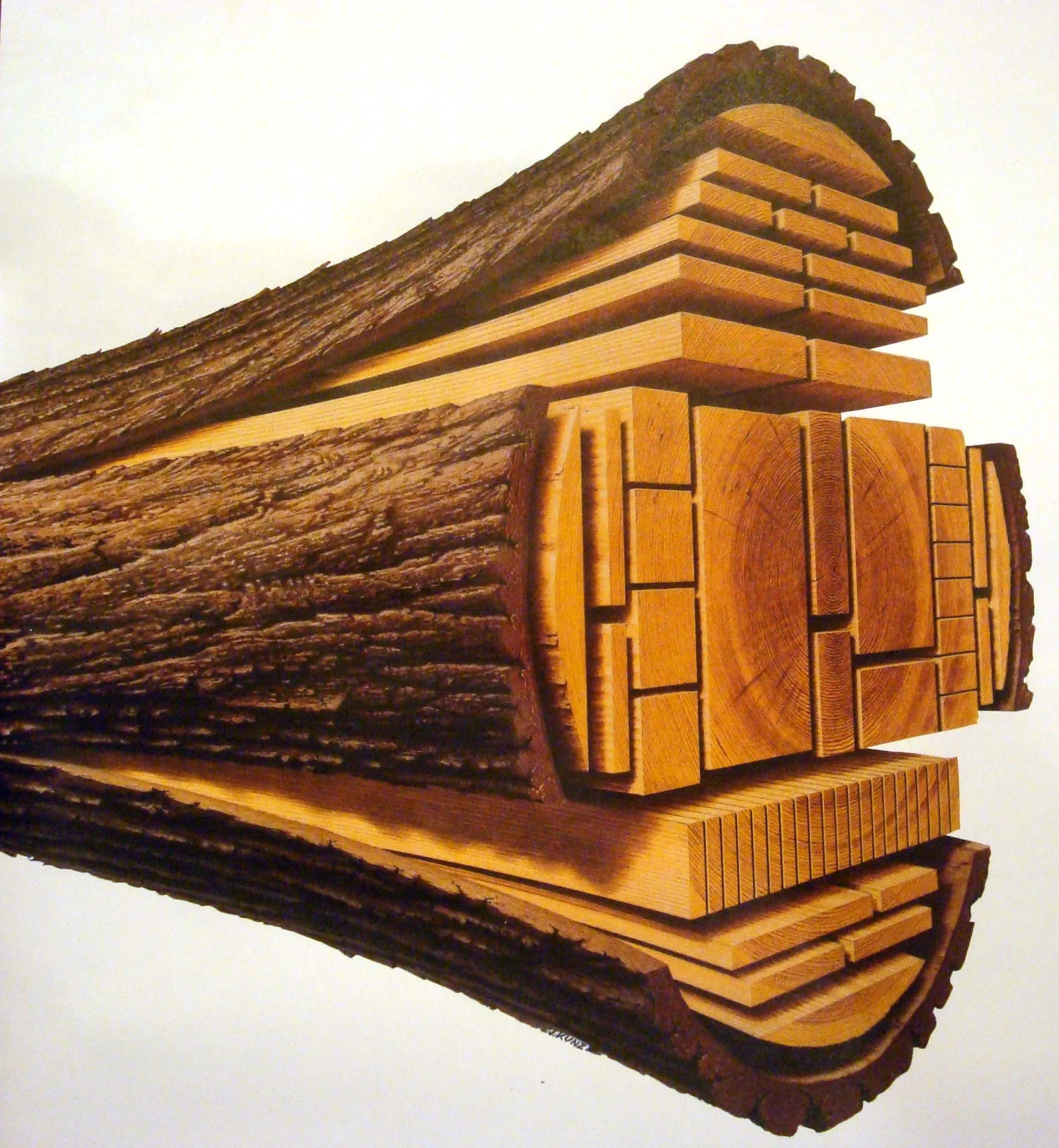

Sawing of Rubberwood Lumber

Rubber wood is susceptible to bacteria and fungi when first cut, so it must be treated quickly. Before treatment, the logs must be milled into rough sawn timber.

Pressurised Preservation Treatment of Sawn Timber

This process takes place inside a vacuum-sealed pressure chamber, which is filled with the treatment liquid. The rough sawn timber are then injected and soaked with treatment liquid that prevents decay and protect it against termite’s infestation. The pressure is progressively increased from 5 up to 10 kgm-3.

Kiln Drying of Sawn Timber

The drying process is done in a Kiln, where excess moisture is removed to attain a uniform moisture level. This allows us to achieve precise moisture levels of 8-10%. This drying process helps in increasing its durability, prevention of surface cracking and splitting. It also enables a decrease in total weight to facilitate cost effective transportation.

Sizing & Sorting of Sawn Timber (Quality Control)

Woodland Nigeria places great emphasis on quality as the rough sawn timber can be damaged if over treated. Once removed from the kiln, highly trained quality control personnel check the processed wood for damage and the correct physical properties. After inspection each piece of wood is resized and sorted accordingly.

Packing, Fumigation & Shipping

Rubber wood is carefully packed in stacking’s of cubic meter bundles and tightly wrapped in waterproof wrappers. This packaging manner ensures freshness, preventing water seepage and staining. Before the rubber wood can be loaded into containers for shipment, it is fumigated, with a light chemical compound to enable its protection from bacteria and fungi infection, a simple spraying of the chemical onto the rubber wood does this.